5083 aluminum plate

The 5083 aluminum plate sheet falls on the aluminium alloy g

5083 H111 & H116 aluminum sheet in 5083 aluminum series is very hot-selling. The H111 & H116 of 5083 h111 aluminum refers to the tempering state in fact. To achieve this temper, the 5083 aluminium sheet after the final annealing has undergone an appropriate work hardening, but the degree of work hardening is not as high as the h11 alloy sheet. So, 5083 h111 aluminum shows adequate strength, good processibility, as well as high corrosion resistance, especially for severe environments. In practical, as a typical marine grade aluminum sheet, al 5083 H111 & H116 is widely used for boat building, vehicle bodies, welding parts, tread plate, etc.

High Corrosion Resistance: The alloy offers excellent resistance to corrosion in marine environments.

Exceptional Strength: Provides high strength, especially in the H116 temper.

Weldability: Good weldability, making it suitable for various fabrication processes.

Formability: The aluminum sheet is easily formable for diverse applications.

Low-Temperature Toughness: Maintains toughness even at low temperatures.

Applications: Commonly used in marine applications, structural components, and other environments requiring corrosion resistance and strength.

| Element | Composition % |

|---|---|

| Manganese (Mn) | 0.40 - 1.0 |

| Iron (Fe) | 0.00 - 0.40 |

| Copper (Cu) | 0.0 - 0.10 |

| Magnesium (Mg) | 4.0 - 4.90 |

| Silicon (Si) | 0.0 - 0.40 |

| Zinc (Zn) | 0.0 - 0.25 |

| Chromium (Cr) | 0.05 - 0.25 |

| Titanium (Ti) | 0.0 - 0.15 |

| Aluminium (Al) | Balance |

| Property | Value |

|---|---|

| Proof Stress | 115 Min MPa |

| Tensile Strength | 270 - 345 MPa |

| Elongation at 50 mm | 15 Min % |

| Hardness Brinell | 75 HB |

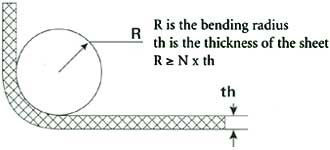

| Bend Radius 90° | 2.5 x t |

| Please note that Mechanical Properties shown are for H111 temper | |

| Property | Value |

|---|---|

| Proof Stress | 215 Min MPa |

| Tensile Strength | 305 MPa |

| Elongation at 50 mm | 15 Min % |

| Hardness Brinell | 85 HB |

| Bend Radius 90° | 3.5 x t |

| Please note that Mechanical Properties shown are for H116 temper | |

Aluminium Alloy 5083 is capable of being bent cold through an angle of 90 degrees around a pin having a radius equal to N times the thickness (t) of the sheet without cracking.

One of the key factors to consider when working with marine grade Aluminium is the minimum bend radius. This refers to the smallest radius that the metal can be bent without cracking or damaging the plates. When the metal is bent beyond its minimum bend radius, the stress on the material becomes too great and it can begin to crack or break. To prevent this and maintain the structural integrity of marine grade Aluminium, it is important to adhere to the recommended minimum bend radii for the specific alloy, temper and thickness of aluminum being used.

Technical Parameters of 5083 H111 & H116 Aluminum Sheet

| Elements | Mg | Si | Fe | Ti | Cu | Mn | Cr | Zn | Others | Al | ||

| Content | 4.0-4.9 | ≤0.4 | 0.4 | ≤0.15 | ≤0.1 | 0.4-1.0 | 0.05-0.25 | 0.25 | 0.05 | Remain | ||

| Typical alloy | 5083 Aluminum Sheet | |||||||||||

| Material temper | h111 | |||||||||||

| Thickness (mm) | 0.1-500 | |||||||||||

| Width (mm) | 100-2800 | |||||||||||

| Length (mm) | Customize | |||||||||||

| Typical product | boat buling, vehicle bodies, welding parts, tread plate,etc. | |||||||||||