1050 h18 Aluminum Plate Sheet

Aluminum Alloys: The alloy designation "1050" indi

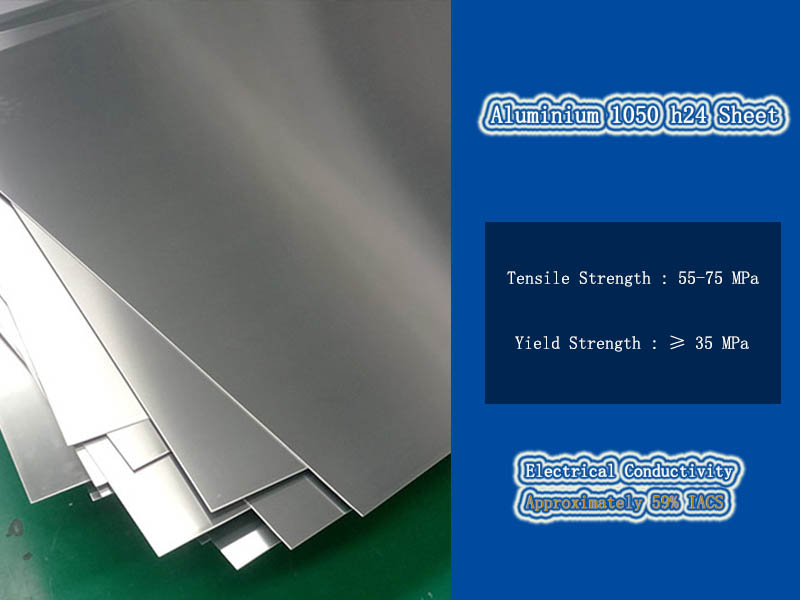

Aluminum 1050 H24 refers to the aluminum alloy 1050 in the H24 temper. This temper designation signifies that the aluminum has been strain-hardened (cold-worked) and partially annealed to achieve the desired mechanical properties.

Aluminum alloy: The alloy designation "1050" indicates that the main alloying element in this aluminum sheet is pure aluminum (99.5% minimum purity). It is a commercially pure aluminum alloy with excellent corrosion resistance and good formability.

H24 Temper: The "H24" temper designation indicates the specific heat treatment and mechanical properties of the aluminum alloy sheet. In the H24 temper, the aluminum alloy is strain hardened (cold worked) and then partially annealed. This tempering provides a balance between strength gain and formability retention.

Aluminum alloy 1050 exhibits excellent corrosion resistance in a variety of environments including atmospheric conditions.

Good formability, easy to shape, bend, and form process.

1050 aluminum alloy can be easily welded by various methods such as TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and resistance welding.

Following are some key properties of Aluminum 1050 H24 Sheet/Sheet:

Mechanical Behavior

| Al 1050 Mechanical Property | Value Range |

| Tensile Strength | 55-75 MPa |

| Yield Strength | ≥ 35 MPa |

| Elongation | ≥ 18% |

1050 h24 Aluminum Plate Physical Properties

| Physical Property | Value |

| Density | Approximately 2.7 g/cm³ |

| Melting Range | 640 to 660°C |

| Thermal Conductivity | 229 W/m·K |

| Electrical Conductivity | Approximately 59% IACS |

1050 H24 Aluminum Plate Thickness Deviation

Thickness tolerances for 1050 H24 aluminum plates may vary depending on the manufacturing process and the specific standard followed.

| Aluminum Plate | Specified Thickness (mm) | Allowable Deviation Range (mm) |

| 1050 H24 Aluminum Plate | 1 | ±0.05 to ±0.1 |

| 1050 H24 Aluminum Plate | 2 | ±0.1 to ±0.2 |

| 1050 H24 Aluminum Plate | 5 | ±0.25 to ±0.5 |

| 1050 H24 Aluminum Plate | 10 | ±0.5 to ±1 |

| 1050 H24 Aluminum Plate | 20 | ±1 to ±2 |

| 1050 H24 Aluminum Plate | 50 | ±1 to ±2 |

| 1050 H24 Aluminum Plate | 100 | ±5 to ±10 |

NOTE: These values are general guidelines and specific tolerances may vary depending on specific requirements, standards, and agreement between buyer and seller. It is recommended to consult the manufacturer or supplier for accurate information on thickness deviation tolerances for 1050 H24 aluminum sheets.

The surface finish of 1050 H24 Aluminum Sheet/Sheet may vary by manufacturer or supplier. It may have a satin finish, which is a smooth and shiny finish that does not require any additional treatment or coating. Other surface treatments such as anodizing or painting can be applied according to specific requirements.

NOTE: Exact dimensions, thicknesses, and certifications for 1050 H24 aluminum sheets/sheets may vary by manufacturer or supplier. It is recommended to consult them for accurate information and to ensure that they meet your specific project requirements.

Due to its moderate strength and good formability, it is suitable for applications requiring both strength and processability.

1050 H24 Aluminum Sheet/Sheet is used in a variety of industries including construction, automotive, signage, and general manufacturing.

It can be used for roofing, cladding, building panels, structural components, and more.

1050 H24 aluminum can be used in a variety of applications including architectural, automotive, signage, and roofing. Here's a breakdown of its use in each application:

1050 H24 aluminum in construction can be used for roofing, cladding, facades, and structural components.

Its lightweight, corrosion resistance and good formability make it suitable for applications requiring durability and aesthetics.

It can be used in the construction of residential, commercial, and industrial buildings.

1050 H24 aluminum is used in the automotive industry for components such as body panels, trim, and interior trim.

Its lightweight properties help improve fuel efficiency and reduce the overall weight of the vehicle.

The corrosion resistance and formability of 1050 H24 aluminum make it suitable for a variety of automotive manufacturing processes.

1050 H24 aluminum is commonly used in the sign industry for both outdoor and indoor signage.

Its excellent corrosion resistance and ability to withstand harsh weather conditions make it ideal for outdoor signage.

The formability of 1050 H24 aluminum allows for the creation of a variety of sign shapes and designs.

1050 H24 aluminum can be used in roofing applications such as shingles or shingles.

Its corrosion resistance, lightweight, and durability make it a popular choice for roofing on residential and commercial buildings.

The 1050 H24 aluminum roof provides durable protection from the elements.

Note: Specific dimensions, thickness, and design considerations may vary according to the requirements of each application. It is always advisable to consult the manufacturer or supplier for accurate information on the use of 1050 H24 aluminum in these specific applications.