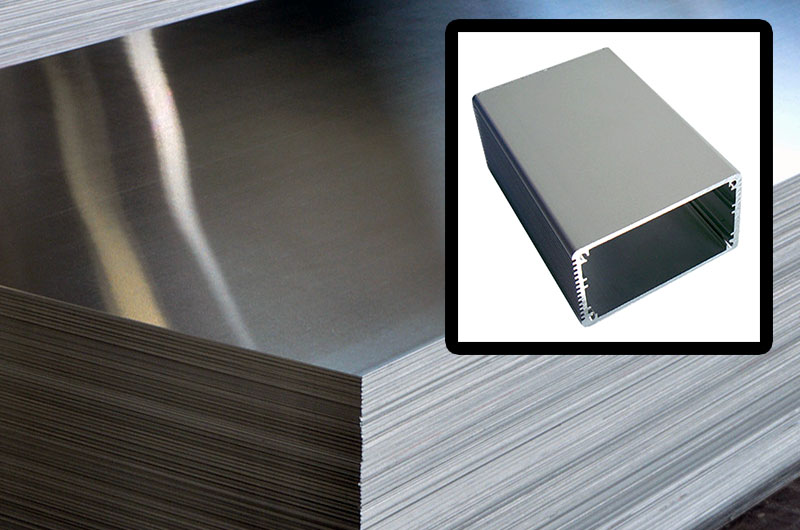

1050 3003 3005 Aluminum Sheet Coil for Power Battery Shell

Aluminum plate for power battery casing is a special type of aluminum plate used to manufacture battery casings for various types of power batteries, including battery casings for electric vehicles (EV), hybrid vehicles and energy storage systems. These aluminum plates are designed to provide structural integrity, thermal management and protection for the internal cells.

Aluminum Sheet Coil for Power Battery Shell Specifications

◆Material: Aluminum alloy, usually 1xxx, 3xxx or 5xxx series

◆Thickness: Varies based on application, but typically ranges from 0.5mm to 5mm

◆Surface treatment: milling, brushing, anodizing or coating on request

◆Strength: High strength-to-weight ratio ensures structural integrity

◆Corrosion Resistance: Aluminum naturally forms a protective oxide layer that enhances its corrosion resistance

◆Conductivity: Aluminum has good thermal conductivity and helps dissipate heat from battery cells

◆Aluminum alloys such as 1050, 3003, and 3005 are often used in the manufacture of power battery casings due to their excellent properties.

1050 aluminum alloy for Power Battery Shell

Application: 1050 aluminum alloy is a commercially pure aluminum alloy with high electrical conductivity. It is commonly used in applications where conductivity is critical, such as electrical conductors and power transmission lines. In terms of power battery casing, 1050 alloy can be used for parts that require good electrical conductivity.

Characteristics: high conductivity, excellent formability, corrosion resistance, weldability.

3003 aluminum alloy for Power Battery Shell

Application: 3003 aluminum alloy is a widely used alloy known for its excellent formability, corrosion resistance and moderate strength. It has applications in various industries, including automotive, construction and electronics. In power battery casings, 3003 alloy can be used for parts requiring good formability and corrosion resistance.

Performance: good formability, corrosion resistance, medium strength, weldability, heat dissipation.

3005 aluminum alloy for Power Battery Shell

Application: 3005 aluminum alloy is a non-heat treatable alloy known for its excellent corrosion resistance and weldability. It is commonly used in applications where corrosion resistance is critical, such as marine environments, chemical storage tanks and building exteriors. In terms of power battery casing, 3005 alloy can be used for parts exposed to harsh environments or corrosive substances.

Properties: Excellent corrosion resistance, weldability, moderate strength and formability.

Alloy | 1050 | 3003 | 3005 | ||||

Temper | O H12 H14 | O H12 H14 | O | ||||

Size specification/mm | Thickness | 0.60-1.60 | 0.60-3.00 | 0.60-2.00 | |||

Type | plate | strip | plate | strip | plate | strip | |

Width | 100.0-2000.0 | 100.0-2000.0 | 100.0-2000.0 | ||||

length | 1000-3 000 | - | 1000-3 000 | - | 1000-3 000 | - | |

Application | power battery shells | ||||||

Aluminum Sheet Coil for Power Battery Shell Advantages

Lightweight: Compared to other metals such as steel, aluminum is lightweight, reducing overall vehicle weight and improving energy efficiency.

Strength: Although aluminum is lightweight, it provides sufficient structural strength to protect the battery.

Corrosion Resistance: Aluminum’s natural oxide layer provides excellent corrosion resistance, extending the life of the battery casing.

Thermal Conductivity: Aluminum’s high thermal conductivity helps dissipate the heat generated during battery operation, which is critical to maintaining optimal operating temperatures and extending battery life.

Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice for battery housings.